In recent years, China's share of global manufacturing output increasing proportion of the total product, is the world's second largest after the US industrial manufacturing country, China, with a huge amount of manufacturing become a veritable "factory of the world." However, the rise of individual consumption are to impact on all aspects of manufacturing enterprises. In the modern market environment, customer demand for customized products are also growing strongly, how more difficult to predict the market demand, volatility under frequent environmental needs, more accurate and efficient decision-making, and optimize enterprise resource allocation efficiency, It is a major challenge facing the manufacturing industry.

K2 thinking of intelligent manufacturing

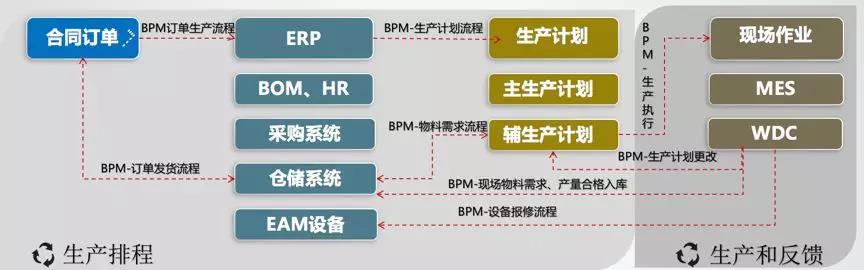

In the manufacturing business, the manufacturing process can be divided into roughly of "Order --ERP-- production plan - field operations," four scenes, by associated data between each scene and related businesses. Output data on one node, the starting point is triggered by a node, it is necessary to implement intelligent manufacturing enterprise business data between systems to get through. Only let through internal business, to achieve the upstream and downstream transmission of data between systems, in order to obtain more accurate data feedback, end to end intelligent production.

K2's Intelligent Manufacturing Keywords

- end-to link:

With carrying data flow, open up the data link between systems, enterprise internal business-end intelligent manufacturing systems.

- Process-driven:

Process-driven core, the feedback process is automatically triggered by the data, access to the most accurate field data and production status, production status and automatically adjust and optimize enterprise resource allocation efficiency.

K2 scenarios in intelligent manufacturing

- Links intelligent robots to obtain production information, feedback triggers production and yield;

- the system links the MES system and the amount of control and feedback;

- Links EAM system, process or equipment failure automatically triggers the fault alarm;

- Links procurement system, triggering the raw materials required under the contract;

- Links warehousing, for accurate matching of raw materials and products based on production and sales plans;

......

As a boost by the digital transformation of enterprises, K2 is committed to continue the application of emerging technologies to process areas, the RPA (robotic process automation) in conjunction with BPM, human liberation, to maximize the value of staff; through the cloud of cloud enterprise applications, business Internet technology ; K2 being a more "smart +" way to promote manufacturing enterprises embrace intelligent management.

K2 Intelligent Manufacturing Solutions

Carrying data flow, enterprise manufacturing intelligence

Forward intelligent process triggers ERP, EAM (device management), MES, procurement, warehousing and other management systems; reverse feedback data trigger the corresponding processes to obtain accurate production, management data, such as production, orders or delivery, equipment operation, etc. state management, to achieve closed-loop manufacturing jobs scenes from production to smart feedback.

With carrying platform enterprise business processes and break information silos

Through the platform links all enterprise management systems, data transmission, information silos refused to allow input and output of all business systems for effective docking, collaborative business process efficiency.

PaaS links with upstream and downstream enterprises to achieve industrial chain

All intelligent manufacturing enterprises using the Internet for Internet demand, production and marketing, and management of data, data on open downstream enterprises to form buying and selling, leasing and other business activities precise data link, thus the formation of the Internet industry.

With PaaS platform to achieve the KPI data analyzed using enterprise reporting system

Reporting systems to achieve business data, big data management data analysis, management to give businesses find gaps, improve decision making, to find accurate data support solutions.